Whether you are a current Fastenal customer looking to utilize our full offering, or a prospective customer who is just learning about all of the advantages of Fastenal, we invite you to explore our offering of industrial services.

Since 1967, Fastenal has set out to provide our customers with more than just the products they need; we set out to provide our customers with a greater level of service designed to help your business maximize your earnings potential. Through our industry-leading 2,600+ locations and our innovative service model, which includes our FAST Solutions technology and a state-of-the-art distribution system, our company is designed to serve you faster and in a more cost-effective manner. "Growth Through Customer Service" is the motto our company is built upon.

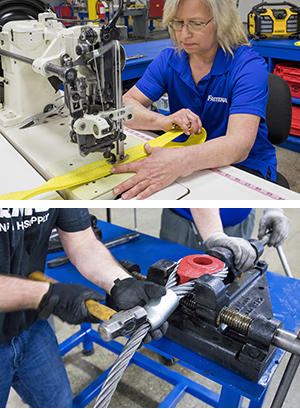

Fastenal Industrial Services is dedicated to supporting our customers with services that drive meaningful cost savings. Our regional team is factory-trained and accredited through industry trainings, strict quality procedures and applicable industry standards.

All styles and configurations based on exact measurements needed.

*Private label programs available on synthetic slings. These can include your company’s name/logo, both on the sling material itself as well as on the sling tag.

Reduces theft and the likelihood of non-approved rigging products being used or other companies placing blame in the event of a failure.

Fastenal makes it easy and efficient to add your logo to a variety of work garments – a powerful way to reduce loss, instill pride, advertise your brand, and shine a spotlight on the great work your people are doing in the field.

No more minimum order quantities. No more dealing with multiple vendors. And no more one-off orders (with set-up fees) for each business unit or project. Fastenal can leverage your company’s custom logo needs and make products easily accessible to local employees – everywhere you operate.

*Laser etching creates a permanent logo and makes for a great promotional giveaway for your customers or employees. Celebrate milestones, anniversaries, company picnics or special events with a high-quality giveaway that will not break your budget.

Fastenal’s Custom Packaging teams can package virtually any combination of parts you need for the job – from basic to complex kits, in large volumes or small quantities. With multiple locations and the latest packaging technology, we’re ready to provide quick turnaround times and the highest level of accuracy.

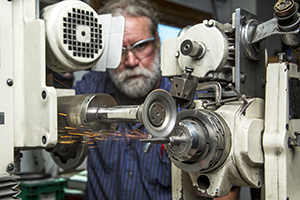

Fastenal’s Tool and Cutter Grinding division not only reconditions used cutting tools; they also produce Fastenal’s high quality line of FMT Element® end mills and a variety of custom cutting tools to customer print.

With 3,000 servicing locations, millions of feet of ready-to-weld blade coil stock, and efficient point-of-use locker solutions, Fastenal will make sure you always have the blades you need to keep your operation running.

Fastenal operates the industry’s only nationwide network of band saw blade welding centers. Our facilities are audited each quarter to maintain their status as Authorized Lenox® Service Centers.

Reduce your liability and free up resources by relying on Fastenal to manufacture your hoses and supply them in ways that save time and money. That can include a Fastenal-managed automated locker solution that ensures you’ll always be ready when a critical hose needs to be replaced.

With a full offering of hose types, end fittings, and diameters, our Hose Fabrication division is ready to produce custom hose assemblies to your exact specifications. That includes kitted hose solutions for OEM production environments as well as replacement kits for preventative maintenance programs. All hoses are cleaned and crimped to the manufacturer’s specifications, with pressure testing available upon request.

Identify type of hose and hose ends needed by providing the type and temperature of fluid being transferred and system pressure.

Fastenal stocks a variety of chain styles and ends to meet your needs. Better yet, we can provide these products as a pre-assembled finished good, saving you time and money. Take the assembly from Fastenal and install it directly to your product – no more buying, stocking, handling and assembling individual components.